Galvanizing Zinc Kettle Replacement Services

Galvanizing Zinc Kettle Replacement Services Specification

- Model No

- Customized / Project-Based

- Installation Guideline

- Provided by technical team, compliant with industry standards

- Motor Power

- Depends on equipment used

- Efficiency (%)

- Up to 99% (Service Efficiency)

- Temperature Range

- Up to 460C (Zinc Bath)

- Speed

- Project-dependent

- Accessories

- Kettle Handling Tools, Safety Gear, Support Structures

- Production Capacity

- Varies, based on plant requirements

- Usage & Applications

- Galvanizing Plants, Hot Dip Galvanizing Lines, Zinc Kettle Maintenance

- Driven Type

- Hydraulic/Mechanical

- Automation Grade

- Manual / Semi-Automatic

- Frequency

- 50-60 Hz

- Type

- Galvanizing Zinc Kettle Replacement Services

- Material

- Special Alloy Steel

- Computerized

- No

- Automatic Grade

- Manual / Semi-Automatic

- Control System

- Custom/Manual

- Drive Type

- Hydraulic / Mechanical

- Voltage

- 220 - 440 V (as per site requirements)

- Power

- Depends on project scope

- Weight (kg)

- Custom as per size & design

- Dimension (L*W*H)

- Customized as per client specification

- Color

- Metallic/Silver

- Capacity

- As per kettle size (customized)

- Features

- High Durability, Precision Fabrication, Corrosion Resistant, Seamless Replacement, On-site Service

- Machine Type

- Replacement/Service-Based

- Surface Finish

- Polished/Alloyed

- Power Consumption

- Depends on crane and ancillary equipment

- Service Coverage

- All major cities and industrial clusters

- Documentation

- Service Report, Quality Certificate

- Applicable Zinc Kettle Size Range

- 2-16 meters length

- On-site Support

- Available (Turnkey Solutions)

- Safety Protocol

- Adheres to international safety norms

- Replacement Timeframe

- 7-20 days depending on site constraints

- Fabrication Tolerance

- +/- 2 mm

- Post-Service Support

- Available (AMC/Annual Maintenance Contract)

- Transport & Logistics

- Managed by service provider

- Corrosion Allowance

- Included in design

- Pre-Installation Assessment

- Yes, included

About Galvanizing Zinc Kettle Replacement Services

Applications and Material Strengths of Galvanizing Zinc Kettle Replacement

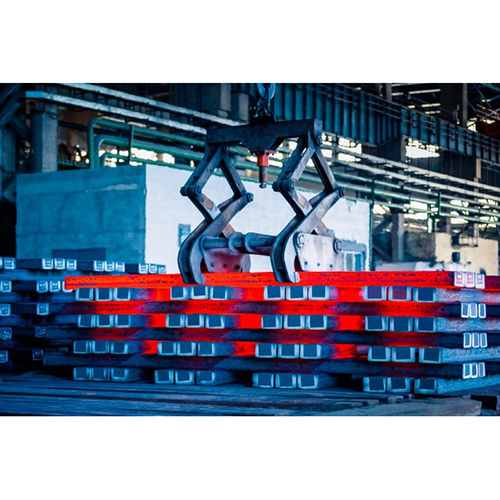

Our Galvanizing Zinc Kettle Replacement Services are ideal for hot dip galvanizing lines, galvanizing plants, and ongoing kettle maintenance needs. Specifically engineered for industrial clusters and large production units, each kettle uses premium special alloy steel, promising exceptional corrosion resistance and precision fabrication. The imposing design tolerance of +/- 2 mm ensures flawless performance in demanding application areas. Choose us for services that provide radiant strength, seamless installation, and long-term durability against corrosion challenges.

Domestic Market Reach, Prompt Delivery, and Flexible Shipping Solutions

Our services cater to clients throughout India, including major industrial zones and cities. We offer express shipping and reliable transport services, ensuring replacement delivery within a favorable timeframe of 7-20 days, depending on project scope and site constraints. Competitive rates and transparent documentation support a seamless process. For urgent requirements, we provide expedited logistics and sample support, giving our customers confidence in our delivery commitment and nationwide presence.

FAQ's of Galvanizing Zinc Kettle Replacement Services:

Q: How long does the Galvanizing Zinc Kettle replacement process take?

A: The replacement process typically takes between 7 to 20 days, depending on site-specific constraints and the size of the zinc kettle. Express shipping and efficient transport services help expedite delivery and installation when necessary.Q: What material is used for the replacement kettles, and why is it beneficial?

A: Our kettles are fabricated from special alloy steel, providing excellent durability, corrosion resistance, and radiant surface finish. This ensures long-lasting performance, minimal maintenance frequency, and consistent service efficiency in demanding industrial conditions.Q: Where are your Galvanizing Zinc Kettle Replacement Services available?

A: We offer comprehensive service coverage in all major Indian cities and industrial hubs. Whether your operation is located in a metropolitan area or a prominent industrial cluster, our technicians can manage on-site assessments, replacements, and support.Q: What kind of after-sales support is included in your services?

A: Our service package includes post-service support such as Annual Maintenance Contracts (AMC), ensuring continued operational efficiency. Additionally, our team provides regular maintenance checks and technical assistance as required.Q: How does your team ensure safety and compliance during installation?

A: We strictly adhere to international safety norms throughout the replacement process. Our technical team follows standardized installation guidelines and provides clients with detailed documentation, including service reports and quality certificates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanizing Design And Consultancy Services Category

Galvanizing Process Design And Optimization Services

Minimum Order Quantity : 1 Unit

Color : Industrial Grey / Blue

Features : High Efficiency, Energy Saving, Minimum Maintenance, Advanced Technology Integration

Accessories : Process Tanks, Pickling Equipment, Dryers, Cooling Zones

Temperature Range : Up to 470C

Speed : Variable, Process Controlled

Hot Dip Galvanizing Plant Upgradation Services

Minimum Order Quantity : 1 Unit

Color : Industrial Grey

Features : Higher Production Efficiency, Energy Saving, Enhanced Corrosion Protection, Environment Friendly, Less Maintenance

Accessories : Fume Extraction System, Safety Controls, Heat Recuperator

Temperature Range : 0C to 550C

Speed : Customizable

Spare Parts Supply Services

Minimum Order Quantity : 1 Unit

Color : Natural, Plated, or Coated (As applicable)

Features : High Durability, Accurate Fitment, Corrosion Resistant, Ready Stock Available

Accessories : Fitting Kits, Fasteners, as required

Temperature Range : Depends on Material & Application

Speed : NA / As per Component

Plant Safety And Automation Services

Minimum Order Quantity : 1 Unit

Color : Grey

Features : High Reliability, User Friendly, Safety Integrated

Accessories : Safety Controllers, Sensors, Control Panels

Temperature Range : 20C to 60C

Speed : Adjustable

An ISO 9001:2015 Company

|

|

GUNATIT ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry