Galvanizing Process Design And Optimization Services

Galvanizing Process Design And Optimization Services Specification

- Production Capacity

- Up to 50 Tons/Day (Design Specific)

- Driven Type

- Electric

- Accessories

- Process Tanks, Pickling Equipment, Dryers, Cooling Zones

- Speed

- Variable, Process Controlled

- Motor Power

- As per Design Requirement

- Usage & Applications

- Industrial Galvanizing, Metal Surface Protection, Anti Corrosion Coating

- Installation Guideline

- Site Survey & Custom Installation Support

- Efficiency (%)

- Over 95%

- Automation Grade

- Automatic

- Model No

- GPO-2024

- Frequency

- 50 Hz / 60 Hz

- Temperature Range

- Up to 470C

- Type

- Galvanizing Process Design And Optimization Services

- Material

- Mild Steel / Stainless Steel Components

- Computerized

- Yes

- Automatic Grade

- Automatic / Semi-Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 380 V / 440 V

- Power

- Customizable as per plant design

- Weight (kg)

- Design Specific

- Dimension (L*W*H)

- Customized Based on Project

- Color

- Industrial Grey / Blue

- Capacity

- As per Client Requirement

- Features

- High Efficiency, Energy Saving, Minimum Maintenance, Advanced Technology Integration

- Power Consumption

- Optimized for Low Consumption

- Machine Type

- Process Line Optimization

- Surface Finish

- Hot Dip Galvanized

- Energy Efficiency Rating

- A+

- Operating Environment

- Indoor/Outdoor Facility

- Documentation Provided

- Design Drawings, Operating Manuals, Process Flow Charts

- Standards Compliance

- ISO 1461, ASTM A123, EN ISO 14713

- Design Software Used

- 3D CAD, Simulation Tools

- Safety Features

- Integrated Safety Interlocks, Emergency Shutoff

- After Sales Service

- Available Across India

- Service Support

- Onsite & Remote Consultancy Available

- Customization Options

- Layout, Tank Size, Process Integration

- Coating Thickness Range

- 40120 Microns

- Project Timeline

- 4-8 Weeks Depending on Scope

Galvanizing Process Design And Optimization Services Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 1-2 Week

About Galvanizing Process Design And Optimization Services

Extensive Application and Commercial Use Areas

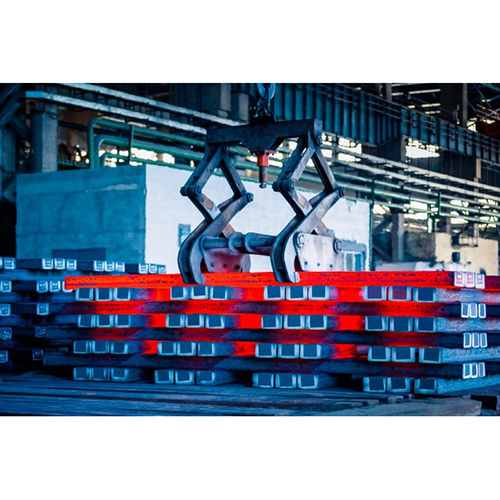

Galvanizing Process Design And Optimization Services are ideal for industries requiring advanced metal protection and anti-corrosion coatings. Major application areas include heavy engineering, automotive, construction, infrastructure, power transmission, and metal fabrication. These systems are commonly used in processes covering both indoor and outdoor environments, ensuring the longevity of mild steel and stainless steel structures. The flexible and scalable solutions make them a cornerstone for industrial, commercial, and infrastructural projects nationwide.

Packaging, Delivery, and Supply Assurance

Each set of Galvanizing Process Design And Optimization Services is carefully packaged to ensure safe transportation, with robust industrial packing materials. Express shipping options are provided, and items can be delivered within 4-8 weeks based on project complexity. Our supply ability guarantees seamless order fulfillment for both single and multiple project requirements. Every package includes essential installation guidelines, documentation, and post-delivery support, ensuring clients receive fully operational solutions quickly and efficiently.

FAQ's of Galvanizing Process Design And Optimization Services:

Q: How does the galvanizing process optimization improve production efficiency?

A: The process uses advanced 3D CAD and simulation tools to design optimized galvanizing lines, which reduces energy consumption, minimizes waste, and increases throughput, resulting in over 95% operational efficiency.Q: What standards do your galvanizing services comply with?

A: Our services adhere to ISO 1461, ASTM A123, and EN ISO 14713, ensuring consistent coating thicknesses, durable finishes, and international quality compliance for all projects.Q: When can I expect delivery after making a purchase?

A: Delivery typically takes between 4 and 8 weeks, depending on the scope and customization requirements of your project.Q: Where can your Galvanizing Process Design And Optimization Services be installed?

A: Our solutions can be installed at both indoor and outdoor facilities across India, customized to fit specific site layouts and operating environments.Q: What types of support are available during and after installation?

A: We provide both onsite and remote consultancy, comprehensive documentation, and after-sales service throughout India, ensuring uninterrupted operation and maintenance assistance.Q: How does your service ensure safety during operations?

A: Every system is equipped with integrated safety interlocks, emergency shutoff mechanisms, and complies with strict industrial safety protocols for secure operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanizing Design And Consultancy Services Category

Hot Dip Galvanizing Plant Upgradation Services

Minimum Order Quantity : 1 Unit

Type : Hot Dip Galvanizing Plant Upgradation Services

Accessories : Fume Extraction System, Safety Controls, Heat Recuperator

Speed : Customizable

Usage & Applications : Enhancing Existing Galvanizing Plants, Modernization, Productivity Improvement

Computerized : Yes

Galvanizing Plant Maintenance Services

Minimum Order Quantity : 1 Piece

Type : Galvanizing Plant Maintenance Services

Accessories : Spare Parts, Maintenance Tools

Speed : Standard/Variable

Usage & Applications : Galvanizing Plant Maintenance, Repair, Overhaul

Computerized : Yes

Quality Testing Laboratory Setup Services

Minimum Order Quantity : 1 Unit

Type : Quality Testing Laboratory Setup Services

Accessories : Standard Lab Accessories Included

Speed : Variable

Usage & Applications : Industrial Laboratory, Quality Assurance, Product Testing

Computerized : Yes

Plant Safety And Automation Services

Minimum Order Quantity : 1 Unit

Type : Plant Safety And Automation Services

Accessories : Safety Controllers, Sensors, Control Panels

Speed : Adjustable

Usage & Applications : Industrial Automation, Plant Safety Monitoring

Computerized : Yes

An ISO 9001:2015 Company

|

|

GUNATIT ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry